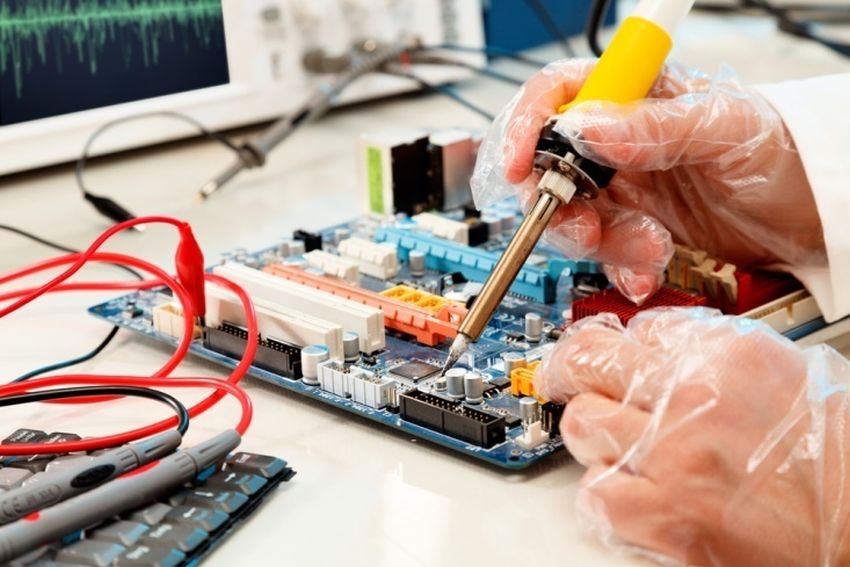

Nowadays, PCB has technologically evolved so much that it is impossible to look down on its importance to any industry. PCB is short for Printed Circuit Boards, and it is a piece of technology that makes everything else tick. We simply cannot imagine any piece of gadget or machinery operating without a circuit board so naturally, we depend a lot on it.

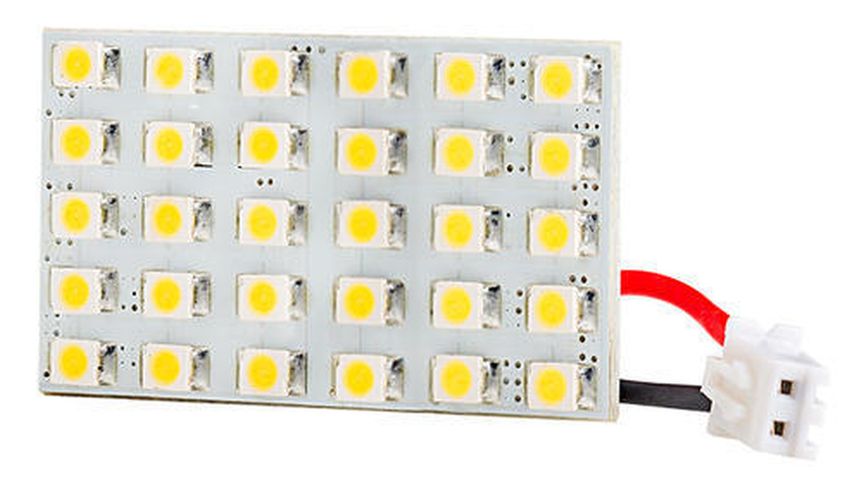

But what about LED lighting in PCB? Well, as with anything in the world, things are changing, with multiple technologies oftentimes combining to create something new.

LED PCB is a clear case of combining two technologies to create something new which will also be more efficient. LED lighting is highly praised for its longevity and long-living.

source:raypcb.com

But there is something more important when it comes to LED that makes it so much effective with PCB. Namely, LED doesn’t heat up the same way as other conventional lightings do. Although it does, it simply won’t do it to a degree as we’ve seen before. An LED won’t be as hot as a lightbulb, for example.

But this doesn’t mean that it can be safely used with printed circuit boards. LED applications with circuit boards do emit thermal heat. It is because of this that any circuit board that wishes to be used with any kind of light-emitting diode must use aluminum and metal as the core. Since both these materials contain thin layers of thermal conductivity, it makes them the most sought-after materials in the market for manufacturers of printed circuit boards.

Page Contents

What Advantages Come With Using LED Printed Circuit Boards?

First off, we have to clarify the need for light-emitting diodes with PCB. Namely, the need comes because more and more circuit boards are manufactured smaller and smaller. This is all down to technological advancements, but it also created a need for people to be able to clearly see the board.

Because of this, manufacturers started adding light-emitting diodes on the surface so that the user could see clearer. Also, there are more benefits to LED when combined with circuit boards, and those are:

source:indiamart.com

- The entire circuit board is quite smaller than traditional ones, making it a great option for many electronic products.

- Due to the materials used for the core, the entire circuit board is quite thermal resistant.

- The ability to dissipate heat.

- Costs far much less than traditional circuit boards due to LED being quite cheap.

- Resistant to dust and moisture.

- Its size makes its usage popular in electronic products where a need for a complex interface is needed.

- It consumes much less power due to its smaller size and LED components than traditional circuit boards.

- It comes in all shapes, sizes, colors, and varieties, making it quite versatile for the user.

Additionally, there are two more important reasons as to why the popularity of LED infused circuit boards is so high. The two reasons directly correlate to the lighting of the board, the integration of the light source, and the ability to increase the lighting.

- You can change the colors easily

- You can achieve various light fixtures

For more information on how the entire board functions with the usage of light-emitting diodes, how they are integrated, and many more, make sure to check this out.

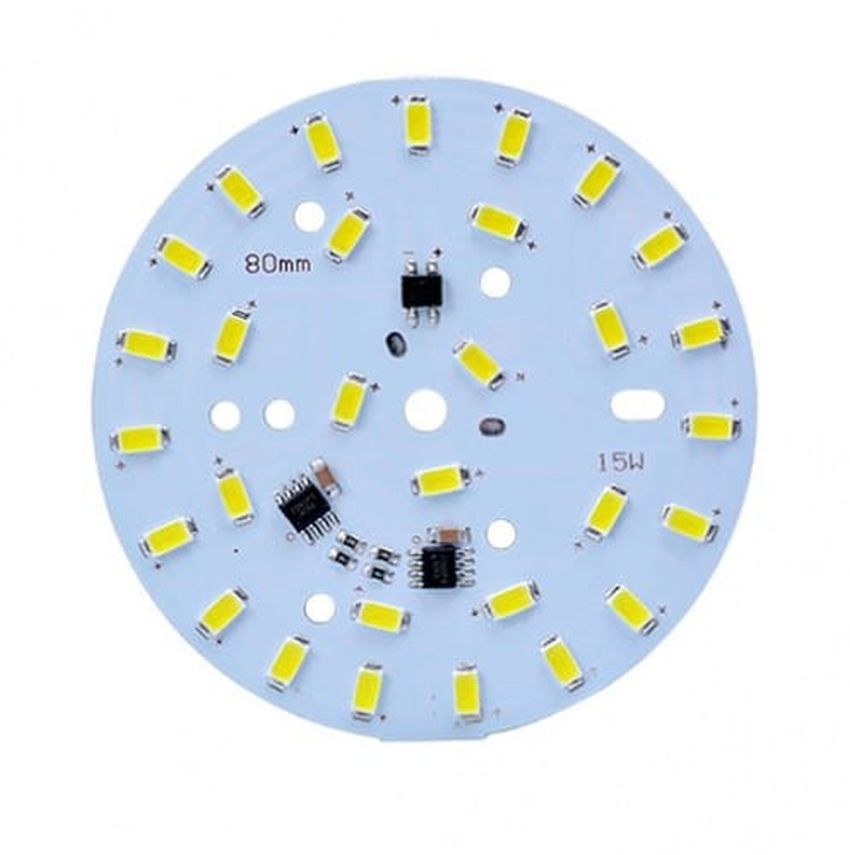

What Makes LED so Popular With PCB?

source:raypcb.com

We briefly touched on why light-emitting diodes are becoming a hot product nowadays, but now we’ll expand the reasons and offer further explanation.

Being an effective lighting solution does beg the question of how or what is the secret behind its functionality. Having also minimal negative environmental impact is yet another reason as to why this product is widely used for circuit boards and general lighting.

Below, we will explain what makes light-emitting diodes a hot commodity nowadays:

· Low Power Consumption

We briefly outlined this when making the previous points in regard to the printed circuit boards. Namely, light-emitting diodes can be up to 8 times more efficient than let’s say light bulbs. Incandescent lighting is generally seen as a costly way to lighting. On average, LED lighting will save you more than 80% of the costs for energy consumption.

· Longer Lifespan

LED has been predicted, and tested, to live up to 25 times longer than incandescent lights. On average, LED will live up to 25,000 hours even if you use it non-stop. This will not only save you a ton of money, but it will also provide you with a more viable solution.

· A More Efficient Solution

We mentioned previously that light-emitting diodes release very little heat, making their usage a prime in PCB. Well, this is all down to the fact that the technology prevents the release of thermal heat, while incandescent lighting does it at a whopping 90%. This makes them extremely efficient and viable in the usage of electronic gadgets, where the need for heating isn’t necessarily the case.

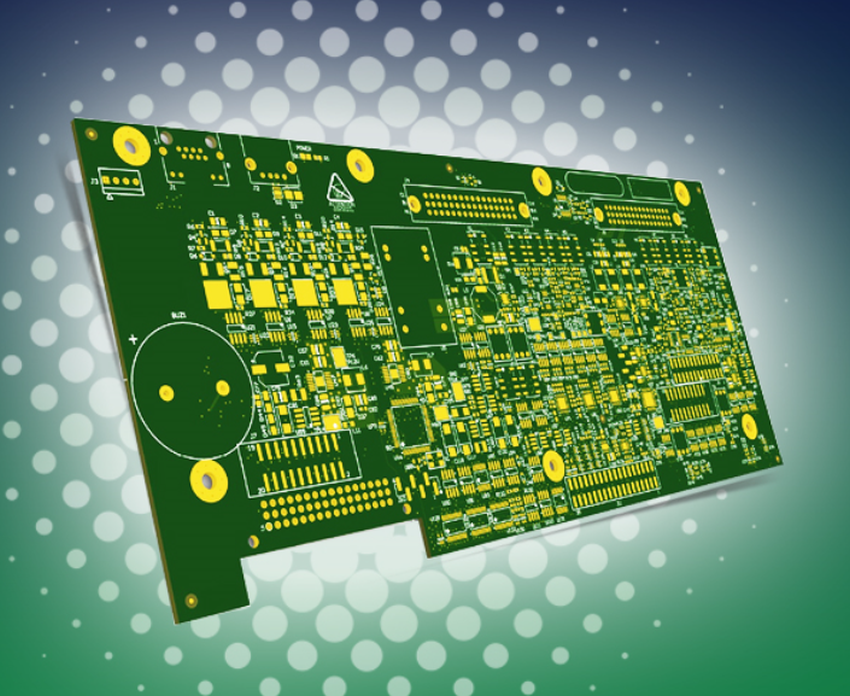

Applications for LED PCB

source:wnie.online

We talked a lot about how a combination of both is mostly used for electronic gadgets and machinery. Well, let’s put that to the test and tell you all about their usage and application.

· Computers

A prime example of their application would be on the computer. As more and more emphasis is placed on RGB lighting with each hardware peace, the only way to achieve it is by using LEC PCB. The motherboard of the computer, nowadays, can emit lighting, and it’s all thanks to these circuit boards.

· Telecommunication

LED circuit boards are also predominantly used in the telecommunication industry. As they have low heat ability, our smartphones benefit greatly by having one less component that emits heat.

· Automotive Industry

Yet another industry that has great use of indicators is the automotive. Cars need some way to tell us about specific things happening on, let’s say, the dashboard. Every light sent to us by our car is through the use of LED PCB. Our taillights, headlights, and tons of other applications use LED PCB as well, making its usage also prime in this industry.