A machine guard is an important safety device used on machines to protect the user from harm. Machine guards are typically made of metal and shield the user from moving parts of the machine while it is in operation. They also help keep debris and chips away from the operator. Guards are commonly found on lathes, mills, routers, grinders, and other similar machines.

There are several reasons why machine guards are needed. First, they protect workers from potential injuries caused by moving parts on a machine. Second, they keep debris and chips away from operators which can cause irritation or even blindness if ingested. Finally, guards provide a physical barrier between the operator and dangerous machinery which can prevent accidents from occurring.

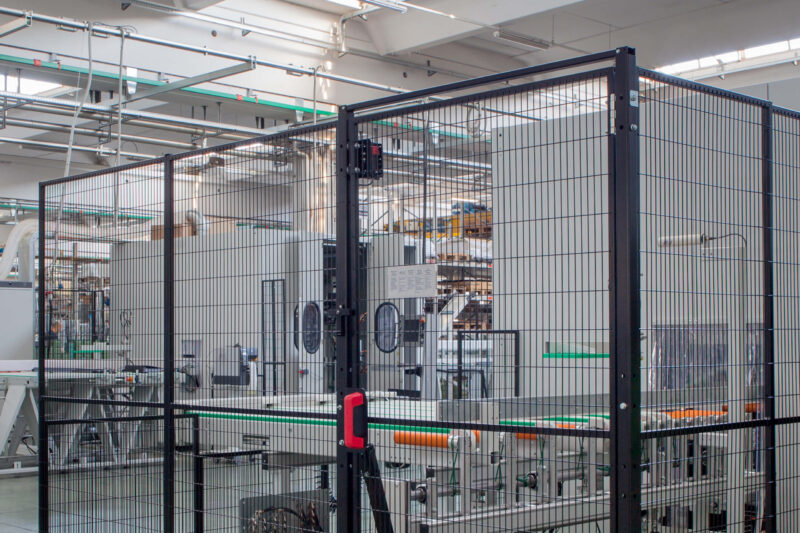

There are several types of machine guards that can be used on machines. The most common type is the enclosure guard which completely surrounds the hazardous moving parts of a machine. There is also the fixed barrier guard which is essentially a fence that sits in front of dangerous machinery and prevents workers from getting too close. Finally, there is the interlocked guarding system which uses sensors to detect when someone is too close to a danger zone and will automatically disable the machine until it’s safe to continue operating. For the best quality machine guards go over this link https://usamachineguards.com/.

Page Contents

What are guards in a machine?

Guards are a machine part that is used to keep the gears and other moving parts of the machine separated. They also help guide balls, screws, or any object into their correct position in order for the machinery to function properly. In some machines, they may be called bushings.

Machinery can be quite complicated with a variety of parts that all have specific functions in order for the machine to work properly. Gears, balls, screws, and other moving parts need to be kept separate and in their correct position; this is where guards come into play. Guards are a type of machine part that act as barriers between the gears and other moving components, as well as help guide objects into their proper place so the machinery can function correctly.

What is the difference between a machine guard and a safeguarding device?

There is a big difference between machine guards and safeguarding devices. Machine guards are specific pieces of equipment that are designed to protect the operator from contact with moving parts on machines. Safeguarding devices, on the other hand, are any type of device or system that helps protect employees from potentially hazardous situations. Some common examples of safeguarding devices include lockout/Tagout systems, guard rails, safety cones, and warning lights.

Which parts of a machine must be guarded?

Nowadays, industrial espionage is a real and constant threat to businesses. As a result, companies must take special precautions to protect their most sensitive information and trade secrets. While there are many parts of a machine that must be guarded, the following three are of particular importance:

The first part of the machine that needs protection is its design. This includes both the schematics and blueprint for the machine, as well as any software or code used to operate it. A company’s competitors could easily use this information to duplicate or improve on their designs. In order to guard against this possibility, companies often keep their designs under tight security control and limit access only to those who absolutely need it.

Another critical part of a machine is its assembly process. If an opposing company were able to acquire detailed instructions on how your machines are put together, they could potentially sabotage them or steal away your employees who know how to do it best! To prevent this from happening, companies usually keep their assembly processes highly confidential and closely guarded by security personnel.

How do you clean machine guards?

Machine guards are an important part of any industrial or commercial machine. They protect the user from injury while the machine is in use. Machine guards can be made out of a variety of materials, including metal, plastic, and wood.

No matter what material they are made out of, all machine guards need to be cleaned on a regular basis. This is because they get dirty over time from grease and other particles that accumulate on them. If these dirt and grease deposits are not removed, they can cause the guard to become slippery and dangerous to use.

The best way to clean machine guards is by using a degreaser cleaner spray. Degreasers work effectively at removing all types of dirt and grease build-up from surfaces. Simply spray the degreaser onto the guard surface and let it sit for a few minutes so that it can soak in properly. Then wipe away with a cloth or paper towel until all residues have been removed. Repeat if necessary.

Some machines may also require special care when cleaning their guards – consult your owner’s manual for more information specific to your make/model.

What are the 4 types of machine guards?

1. Fixed Guards

A fixed guard is a physical barrier that blocks the operator’s access to hazardous machine motion. Generally, they are used in conjunction with other types of guards such as interlocked or adjustable guards. Types of fixed guarding include barriers, shields, and fences.

2. Interlocking Guards

An interlocked guard uses one or more mechanical devices to prevent the accidental opening of a hazard while it is being guarded. This type of safety device usually employs some sort of locking mechanism which must be disengaged before the cover can be opened and the machine activated. The most common form of interlock utilizes sliding door mechanisms which block access to rotating blades when closed. Other examples include key-activated switches, pressure pads, and infrared beams.

3. Adjustable Guards

Adjustable guards provide varying levels of protection depending on the task at hand. They can be easily adjusted to fit around different size objects or openings without having to remove them entirely from the machine perimeter as fixed guards do. Typically made from light materials like sheet metal or plastic, these types of guards typically need frequent adjustment when working with varied-sized parts during production runs.

4. Self-adjusting Guards

Self-adjusting Guards a self-adjusting guard dynamically responds to changes in workpiece size. There are three types of adjustable guards: manual, hydraulic, and pneumatic. Manually adjustable guards require the worker to adjust them by hand, while hydraulic and pneumatic adjustable guards use pressurized oil or air to move the guard components.