Ultrasonic cleaning is a cleaning process that is mainly used for equipment and devices. It uses high-frequency sound waves which are transmitted through a liquid. The process is both cost-effective and time-saving.

You need to have a clear understanding of the ultrasonic cleaner to ensure that you do not damage its parts. Overusing it can also cause harm to your costs as you spend on frequent repairs.

So, how should you take care of your ultrasonic cleaning tools? The article will look at six tips to help you get the best results. Let’s dive in!

Page Contents

1. Consult a Professional

img source: unsplash.com

It may seem obvious but this is an important point. If your ultrasonic cleaning tools ever malfunction, call a professional. Repairing it yourself can cause harm to both you and the cleaner.

Consulting a professional or a cleaner who understands ultrasonic cleaning is important for two reasons. One, it helps you not damage the machine further. Ultrasonic cleaners work on a very high voltage and should not be repaired without supervision. Two, like any electrical equipment, if you open the machine, you will lose the warranty.

Make sure that you reach out to a professional instead of attempting to repair the system by yourself. The same goes for experimenting with the solutions. The manufacturer’s manual should be your guide here. Only use solutions and parts that are approved. Follow the right process to get the most out of your ultrasonic cleaners.

That sounds like common sense, but you’d be amazed at the number of people who decide they know better than the manufacturers or the producers of ultrasonic cleaning solutions. By following best practices you will avoid any expensive or silly mistakes that could damage the cleaning equipment or the objects you want to clean.

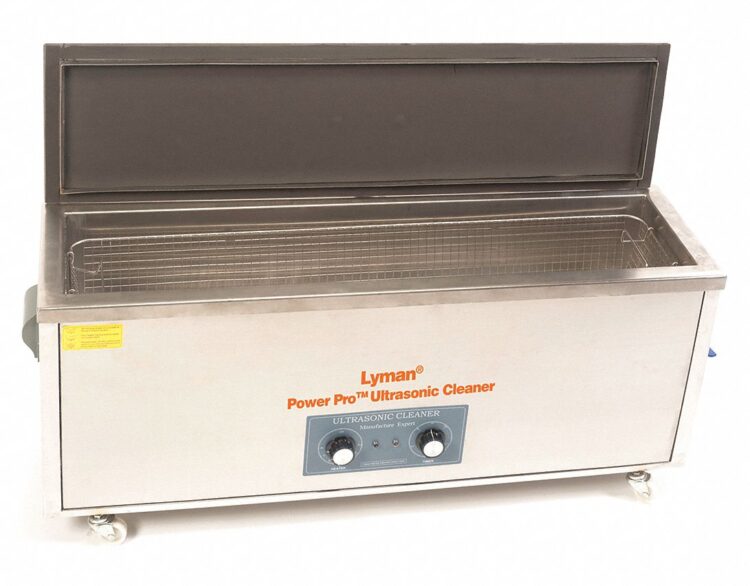

2. Ensure That You Do Not Plug-In An Empty Cleaner

img source: grainger.com

Plugging an empty ultrasonic cleaner can cause the transducer to burn out. Always make sure that the tank is properly filled before you switch it on.

Fill it up to the recommended level before switching it on to ensure that you do not cause any damage to the cleaner. It’s an easy mistake to make, especially when you remove the plug but forget to switch off the socket. It could cause damage if fragile jewelry or stones are present in the ultrasonic cleaner.

3. Avoid Overloading

If you have a lot of parts to clean, you may want to bundle them together and clean them all at once. Doing this can cause damage. When you overcrowd the cleaner, the many surfaces may rub against each other and can cause minor to major scratches.

Ensure that you break down the parts into smaller units when cleaning them. It might take longer but the result will be worth it. Saving time, in this case, may lead to some wear and tear on your parts- something you should avoid.

4. Get the Solvent Right

img source: indiamart.com

Ultrasonic cleaners rely on liquids for the cleaning process. While water is also effective, using other solvents has the best effect on contaminants. These include dirt, soil, oil, light grease, and carbon.

These require alkaline solutions that can rid the parts of tough stains due to their high pH value.

They work well with metals like steel, stainless steel, and titanium. An important thing to note here is that steel also rusts quickly. To avoid that, use ultrasonic cleaning solutions created by companies like L&R Ultrasonics which have an in-built rust inhibitor or use a rust inhibitor.

For other delicate steels like aluminum, you need acidic solutions to clean. These solutions have a lower pH value and are best suited for gentle cleaning action. You can also use these for parts that have been damaged by water.

For the even more delicate parts, such as parts of an electronic device or surgical tools, you will need a solution with a neutral pH solution. It is perfect for cleaning light contamination like dust or light dirt particles. These solutions are best suited for ceramics, precious metals, and jewelry cleaning.

In addition to this, ensure that your solution is not flammable. The ultrasonic cleaner gives off a powerful vibration that can heat the solution. It can lead to a fire if not checked. Always use a water-based solution for your cleaner.

5. Ensure That You Do Not Plug-In An Empty Cleaner

img source: lincos.tools

Plugging an empty ultrasonic cleaner can cause the transducer to burn out. Always make sure that the tank is properly filled before you switch it on.

Fill it up to the recommended level before switching it on to ensure that you do not cause any damage to the cleaner. It’s an easy mistake to make, especially when you remove the plug but forget to switch off the socket. It could cause damage if fragile jewelry or stones are present in the ultrasonic cleaner.

6. Use the Right Time and Temperature

img source: clevercreations.org

There is no standard right time and temperature for ultrasonic cleaners. Most of these cleaners work best in the 135 degrees to 150 degrees Fahrenheit range. It provides good microscopic cleaning energy.

Higher heat can help soften dirt at a faster rate. However, it also accelerates evaporation and can damage softer metals.

One thing you should know about ultrasonic cleaners is that time and temperature are inversely proportional. If you use lower temperatures for critical applications, you may need to leave the parts in the solution for a longer period.

Bottomline

Use these tips to use your ultrasonic cleaners for a long time without any damage or extra repair costs. These tips will not only help you maintain your cleaning tools better but also helps in protecting yourself from injury.

If the equipment does malfunction, reach out to a professional. There are a few things you can do to maintain your cleaning tools. These include using the right solvent, checking the time and temperature, and avoiding overloading.

In addition to this, make a mental note to never plug in your cleaning tool with an empty tank. Keep these tips in mind to better manage your cleaning tools and parts and reduce wear and tear.