Dot peen marking machines allow manufacturers to automate the marking part of the manufacturing process to ensure 100% reliable part tracing.

Dot peen marking machines are used by manufacturers to increase production throughput and reallocate valuable resources. These machines also give parts accurate identification marks, eliminating the need to rework, scrap, or test highly legible products.

Page Contents

How Do Dot Peen Marking Machines Work?

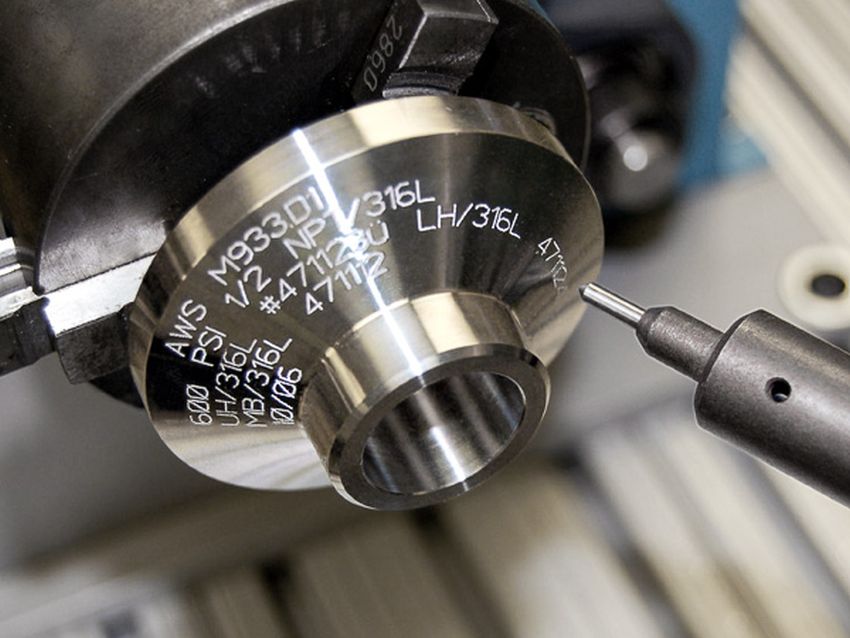

These machines use a very simple pneumatically driven method of marking pins to stamp (or peen) very small, closely spaced dots to form lines. The marking pin has an X and Y marking axes placed very close together to deliver precisely timed marks. The marking pin uses a highly accurate and powerful five-phase stepper motor that enables consistent and accurate marking on all products.

source:pannier.com

This type of technology is often referred to as pin marking technology due to the method of using marking pins to mark products. This marking pin delivers accurate and very fast results while minimizing the exposure of the product surface. With dot peen marking machines you can mark anything from texts, logos, 2D data matrix codes, and more. With these machines, you control the quality and depth of the marking process by adjusting the marking settings such as air pressure, dot spacing, and distance between the pin and the product (part).

According to Heatsign.com, peen dot marking represents the ideal method of permanent direct part marking onto a metal component. 2D data matrix barcodes can store large amounts of data on them. These codes are placed onto metal components to carry that data, and they are done using dot peen marking. The marking is done through a variety of different character styles, sizes, and depths.

Fixturing

Before any dot peen marking machine works on any piece of the metal component, it must be firstly held firmly to deliver a good quality mark.

Work Piece Material

source:pannier.com

While dot peen marking machines are used to mark a variety of metal components, some are easier to mark than others. A general rule of thumb is considered that the harder the material, the shallower the depth of the mark will be. Another factor that plays a huge part is the type of material. The material type greatly influences the life of the stylus tip, the harder the material the easier the stylus tip wears down. However, one way to increase the lifespan of the stylus tip is to adjust the angle to reduce the chance of chipping.

Surface Finish

source:pannier.com

The surface of the material plays a huge role in determining the success of the marking. Smoother surfaces and metal components with well-finished surfaces are easier to mark than other, rough, surfaces. It’s safe to say that the smoother the surface, the easier the mark can be read and the rougher the surface, the harder for the marking to be read.

Marking on Uneven Surfaces

source:pannier.com

Yet another area where dot peen marking can be used is on uneven surfaces. While this poses a great challenge, dot peen marking can work on other areas that are not completely flat. However, the depth of the mark will vary across that surface.